In the steel industry, rolling mill and mill are vital equipment. They play an indispensable role in the metal processing process. Rollers, as the main working tools for rolling, are widely used in the production of steel products. This article will explore the basic structure, working principle and classification of rolling mills and mills.

Overview of Rolling Mill

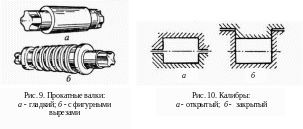

A rolling mill is a device that processes metal materials into various shapes and sizes through one or more pairs of rolls. According to different application requirements, rolls can be divided into smooth rolls, calibration rolls and special rolls. Smooth rolls are usually used for rolling plates, strips, etc., while the working surface of calibration rolls is grooved for processing more delicate products.

Structure of Roller

The roll consists of a working part (roller barrel), a neck for mounting in the bearing and a cross-shaped end for connecting the roll to the drive. The main task of the roll is to formulate the rolling pattern, and to achieve efficient processing of different materials by precisely adjusting the caliber (that is, the arrangement of the grooves on the roll surface).

Classification of rolling mills

Based on the purpose, the number and arrangement of rolls in the stands, and the number of stands arranged relative to each other, rolling mills can be divided into different types:

Classification by purpose: rolling mills are divided into primary rolling mills for rolling semi-finished products and finishing mills for rolling finished products.

Classification by the number of rolls: rolling mills can be divided into two-roll mills, three-roll mills, and multi-roll mills, etc.

By stand arrangement: it can be a single stand or multiple stands, and the stand arrangement includes linear and sequential.

Working process of rolling mills

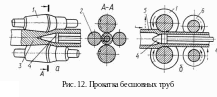

The working process of rolling mills is usually divided into multiple stages, including primary rolling, finishing rolling, and final surface treatment. For example, in the production process of seamless pipes, the round ingot is first punched by a piercing machine to form a thick-walled casing, and then the casing is rolled into a pipe by an automatic rolling mill, and finally the wall thickness is adjusted by multiple rolling by the return roller.

Seamless pipe production

The core of seamless pipe production is to process the casing by transverse spiral rolling technology. Using a mandrel and a special piercing machine, after heating, the pipe is further rolled by an automatic rolling machine to ensure that the outer diameter and inner wall of the pipe are smooth. Through this process, the quality of seamless pipes is effectively guaranteed.

Welded pipe production

Compared with seamless pipes, the production process of welded pipes is relatively simple and the cost is also low. The blank of the welded pipe is a strip with a width equal to the length of the pipe circumference, which is connected into a pipe by a welding process. Small-diameter pipes are formed in a continuous rolling mill, while large-diameter pipes require a higher-specification press or bending roll mill.

Coordination between mills and rolling mills

Mills are mainly used for finishing and surface treatment, while rolling mills are responsible for rough processing and forming. In many steel production processes, the coordinated work of rolling mills and mills is essential to ensure the dimensional accuracy and surface finish of the products. For example, when rolling billets and plates, it is often necessary to go through multiple rolling and grinding to ensure that the quality of the final product meets the standards.

Conclusion

As vital equipment in steel processing, rolling mills and mills play an irreplaceable role. From rolling billets and slabs to the production of seamless and welded pipes, they ensure the precise size and excellent surface quality of steel products. Through reasonable rolling mill configuration and fine processing of mills, the steel industry is able to produce high-quality products that meet market demand.

With the advancement of technology, the efficiency and precision of rolling mills and mills are constantly improving, and steel production will develop in a more efficient and environmentally friendly direction in the future.