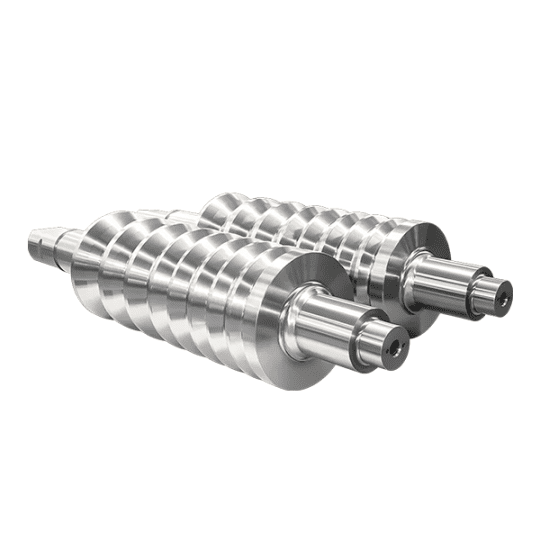

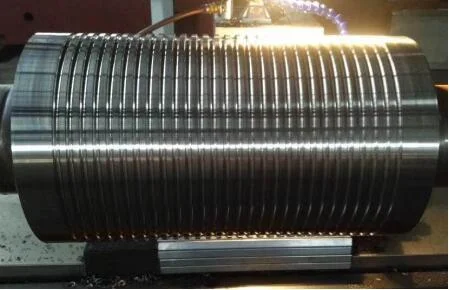

The high-speed steel rolls produced by CYKC are tailored to meet specific rolling requirements. HSS Rolls are developed according to the rolling material, mill sequence, and rolling characteristics.Through component and heat treatment technique, HSS Rolls hardness in the working layer can reach 80-85HSD; the matrix in martensite contains V, W, and Mo compound carbide to ensure even hardness and aperture abrasion in the working layer.This kind of roller applies to finishing racks to expand the working period and improve the surface quality of rolling materials.

Examples include:

HSS Rolls for the finished racks of bar rolling mills.

High-toughness rolls for slitting racks.

HSS Rolls for intermediate rolling stands.

Heat crack-resistant rolls for roughing stands.

HSS Rolls for controlled cooling and rolling lines.

CYKC is also developing a new generation of high-strength, heat crack-resistant, and wear-resistant rolls for endless rolling production lines. CYKC has optimized the composition of high-speed steel rolls to prevent segregation issues in centrifugal production. The company has also enhanced the heat treatment process to ensure uniform roll hardness.

High strength, good heat resistance, good surface roughness of rolled material, high hardness, good wear resistance.

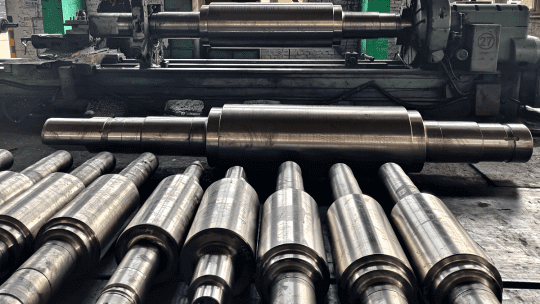

Compared with traditional ductile iron roll and high Ni-Cr roll, HSS Rolls have higher wear resistance and higher single-pass over-steel volume, saving the roll change time, improving mill operating rate, reducing roll consumption and reducing Production costs, improve the overall efficiency of the factory.

HSS Rolls is used for the rough rolling stand of the bar and wire rod rolling mill, for the intermediate rolling stand, and for the finishing rolling stand of the bar rolling mill of the normal temperature rolling production line.

HSS roll chemical composition

| Chemical Analysis | |||||||||

| Grades | C | Si | Mn | Cr | Ni | Mo | W | P | S |

| HSS | 1.5-2.2 | 0.3-1.0 | 0.4-1.2 | 3.0-8.0 | 0.0-1.5 | 2.0-8.0 | 1.0-0.8 | ≤0.03 | ≤0.03 |

| Physical Properties | ||

| Grades | Hardness | Tensile strength |

| HSS | 60-90HSD | ≥400MPA |

Company profile

Liaoning Chengyue Minerals Co., Ltd. specializes in supplying consumables for steel and rolling mills. We are confident we can provide customers with high-quality products and better services. Our main products include cast iron rolls, cast steel rolls, semi-steel rolls, high chromium steel rolls, high-speed steel rolls, a total of more than 20 varieties. We can produce 60,000 tons of centrifugal composite, conventional rolls and roll rings annually. Our products are sold to steel companies all over the world. We have established long-term and stable cooperative relations with customers in more than 20 countries around the world.

Our service

We provide one-stop service, from order submission, design, delivery to after-sales service, to meet all your needs, so that you can feel our concentration and professionalism in every link.

Why choose us

Research and design

We have a professional technical team with rich industry experience

Fast delivery, reasonable price

Excellent after-sales service

Packing&Shipping

We have a professional packaging team to ensure the integrity and safety of goods.

Whether it is land transportation, sea transportation, air transportation, we can choose the most stable transfer mode according to the needs of customers to ensure the rapid delivery of products.