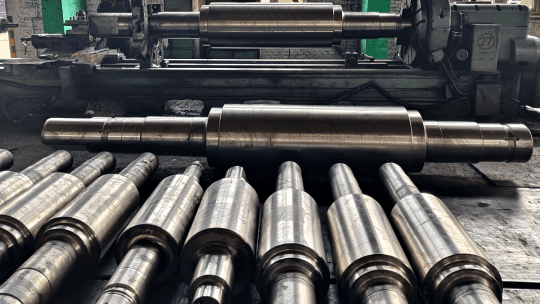

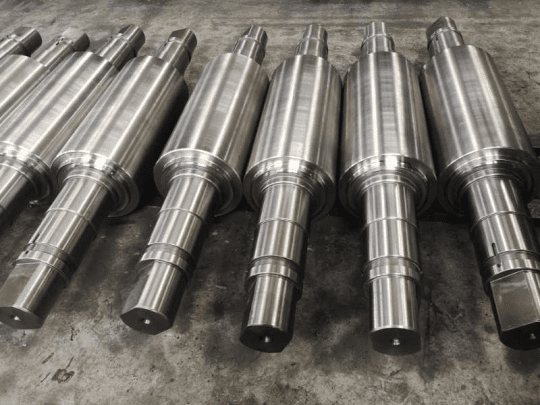

Pearlite Ductile Iron Rolls have high strength and toughness, Pearlite Ductile Iron Rolls can withstand high pressure and impact loads, and are not prone to breakage or deformation, ensuring the stability of rolling.

Pearlitic Ductile Iron Roller is suitable for roughing mills and can meet the rough rolling needs of metal billets of different sizes and materials, including steel billets, aluminum billets, etc. Compared with some more expensive roll materials. Pearlitic Ductile Iron Roller have lower manufacturing costs, but Pearlitic Ductile Iron Roller performance can still meet the requirements of roughing mills and are cost-effective. Perlitic Nodular Cast Iron Rolls have high strength and toughness, can withstand high pressure and impact loads, and are not prone to breakage or deformation, ensuring the stability of rolling. Perlitic Nodular Cast Iron Rolls can maintain good hardness and shape stability at high temperatures, ensuring the dimensional accuracy of rolled products. Perlitic Nodular Cast Iron Rolls can improve the production efficiency of the finishing mill, reduce downtime during the production process and the frequency of roll replacement, thereby reducing production costs. Pearlite Ductile Iron Rolls are suitable for large blooming mills, continuous rolling mills of section steel, and coarse and medium rolling of rod and wire.

Suitable for rough rolling, intermediate rolling and finishing rolling.

| Chemical Analysis | ||||||||

| Crades | C | Si | Mn | P | S | Cr | Ni | Mo |

| SGPI | 3.1-3.5 | 1.2-2.0 | 0.4-1.0 | ≤0.05 | ≤0.05 | 0.3-0.6 | 1.5-2.0 | 0.3-0.8 |

| SGPII | 3.1-3.5 | 1.2-2.0 | 0.6-1.0 | ≤0.05 | ≤0.05 | 0.4-0.8 | 2.0-2.5 | 0.3-0.8 |

| SGPIII | 3.1-3.5 | 1.2-2.0 | 0.3-0.8 | ≤0.05 | ≤0.05 | 0.3-0.8 | 3.0-3.5 | 0.3-0.8 |

| Physical Properties | ||

| Grades | Hardness | Tensile strength |

| SGPI | 45-60HSD | ≥450 MPA |

| SGPII | 55-65HSD | ≥450 MPA |

| SGPIII | 60-70HSD | ≥450 MPA |