Tungsten Carbide Rolls: The Key to Superior Steel Mill Performance

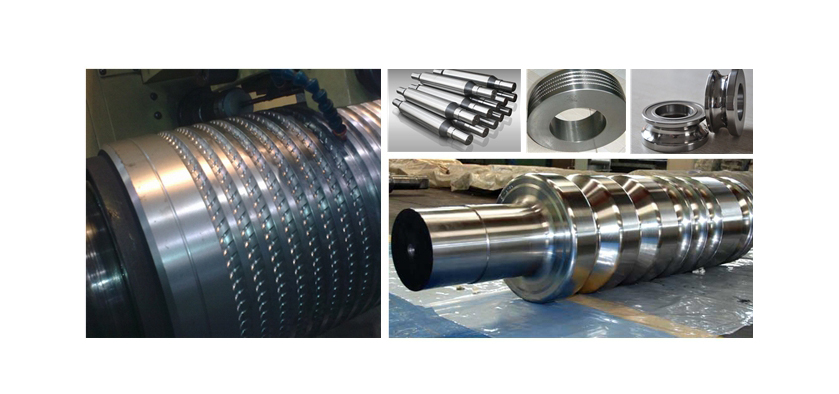

In the demanding environment of steel production, every component must deliver maximum reliability and efficiency. Among the most critical is the mill roll. At CYKC GROUP, we provide advanced tungsten carbide rolls and composite roll solutions engineered to meet the specific challenges faced by modern steel mills.

Why Choose Tungsten Carbide Rolls for Your Steel Mill?

Tungsten carbide rolls are not just an alternative to traditional forged steel or iron rolls; they are a significant upgrade. Their exceptional material properties offer tangible benefits that directly impact your bottom line:

Exceptional Wear Resistance: The extreme hardness of tungsten carbide rolls translates to a dramatically longer service life. This reduces the frequency of roll changes, minimizes downtime, and increases overall mill availability.

Enhanced Thermal Resistance: These rolls maintain their structural integrity and hardness even under the high thermal stresses encountered during high-speed rolling, preventing issues like heat checking and spalling.

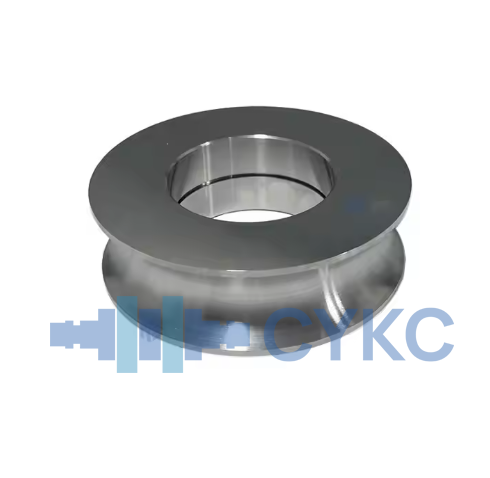

Superior Surface Finish: The inherent rigidity and stability of tungsten carbide rolls contribute to exceptional dimensional accuracy and a superior surface finish on the final steel product, whether it's wire rod, bar, or strip.

Our Tailored Approach to Tungsten Carbide Roll Solutions

We understand that no two mills are identical. A one-size-fits-all approach does not work for critical components like rolls. CYKC GROUP distinguishes itself through a consultative partnership:

Precise Grade Selection: Our expertise lies in matching the perfect tungsten carbide roll grade to your specific application. We consider factors including mill type, stand position, rolled product, and desired outcomes to ensure optimal performance.

Extensive Product Range: Through our manufacturing partners, we offer one of the most comprehensive portfolios of tungsten carbide roll grades. This allows us to provide a solution precisely tailored for wear resistance, toughness, or a specific balance of both.

Quality Assured: ISO 9001:2015 Certification

Quality is the foundation of our offering. The tungsten carbide rolls we provide are manufactured under a quality management. This global standard ensures full compliance with industry requirements at every stage—from raw material sourcing and powder metallurgy to sintering, finishing, and inspection. You can trust that every roll delivers consistent, reliable, and predictable performance.

The CYKC GROUP Difference: Creating Value for Your Operation

Our mission extends beyond supplying products. We strive to create lasting value and make a measurable difference in your productivity:

Reduced Operating Costs: The extended lifespan of our tungsten carbide rolls lowers your cost per ton rolled, providing a strong return on investment.

Expert Technical Support: Our team offers deep industry knowledge and support, helping you implement the best roll solution for your unique needs.

A Partnership for Progress: We work with you as a strategic partner, dedicated to optimizing your rolling processes and achieving your production goals.

Ready to upgrade your mill's performance with high-performance tungsten carbide rolls? Contact CYKC GROUP today to discuss your specific requirements and discover how our tailored solutions can drive efficiency and quality in your operation.

Contact us: cykc@cykcgroup.com.cn