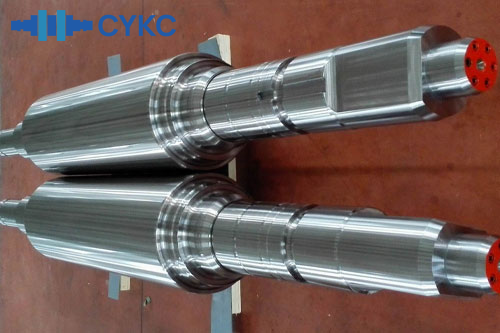

In the steel manufacturing process, the quality of the roll plays a vital role in the quality of the product and production efficiency. In order to ensure the smooth progress of the rolling process, it is crucial to select suitable roll steel and cast iron rolls. This article will explore the requirements, characteristics and selection criteria of roll steel and cast iron rolls in depth.

1. Roll steel requirements

One of the key properties of roll steel is hardenability. Hardenability directly affects the depth and durability of the hardened layer of the roll. In order to ensure high hardenability, it is usually necessary to select steel grades with sufficient stability of undercooled austenite in the two transformation zones. In this way, the roll can achieve martensitic transformation at the minimum cooling rate (such as cooling in oil) and provide sufficient hardness and strength.

Deep hardenability is also crucial, which determines the depth of the hardened layer on the roll surface. In order to obtain a high depth of martensitic transformation, it is necessary to appropriately increase the alloying elements (such as silicon, boron, chromium, etc.) and carbon content in the steel. In particular, the chemical composition of the steel is optimized to ensure that the steel roll has strong hardness and wear resistance while maintaining high rolling accuracy.

2. Wear resistance and strength of roll steel

Under high-intensity working conditions, the wear resistance and contact strength of the roll are crucial to the working performance. The roll needs to withstand huge contact stress, so the contact strength of the steel must be higher than the contact stress generated during rolling to ensure stable working performance.

In addition, wear resistance is one of the core characteristics of roll quality. Highly wear-resistant rolls can maintain high efficiency for a long time and reduce the occurrence of failures. Improving the surface hardness of roll steel and increasing its carbon and chromium content are both effective ways to improve wear resistance.

3. Selection and application of cast iron rolls

Compared with steel rolls, cast iron rolls have unique advantages in wear resistance. Cast iron rolls, especially cast iron containing spherical graphite, have relatively high wear resistance and hardness, and during operation, graphite particles can effectively reduce the damage of the metal matrix.

The wear resistance of cast iron rolls is closely related to the graphite morphology inside them. When graphite exists in spherical form, its wear resistance is 30% to 40% higher than that of conventional gray cast iron. In addition, low-phosphorus cast iron rolls have higher mechanical properties (strength, elongation, impact toughness, etc.) and durability than rolls made of ordinary cast iron. Their resistance to breakage is also significantly improved, making them suitable for high-load, high-strength rolling environments.

4. Metal alloying of rolls

In order to further improve the wear resistance and breakage resistance of rolls, metal alloying has become an important improvement measure. By adding alloying elements such as chromium, vanadium, molybdenum, nickel and boron to cast iron, the surface hardness, grain structure and carbide distribution of the rolls can be significantly improved. These alloying elements not only improve the wear resistance of the rolls, but also improve their heat treatment properties, enabling the rolls to maintain good stability and service life in high temperature environments.

5. Selection criteria for roll steel and cast iron rolls

When selecting roll steel and cast iron rolls, in addition to wear resistance, factors such as hardness, impact resistance, chipping resistance, and machinability also need to be considered. For steel rolls, the higher the hardness, the stronger the wear resistance, but its chipping resistance may decrease, so these properties need to be balanced when selecting.

For cast iron rolls, especially low-phosphorus cast iron, although its hardness may be lower, its durability and resistance to breakage have been significantly improved. Therefore, the selection of suitable roll materials needs to be optimized according to specific production conditions and rolling requirements.

6. Conclusion

The selection of rolls has an important impact on the efficiency and product quality of steel production. Roll steel should have high hardenability, high wear resistance and high contact strength, while cast iron rolls have natural advantages in wear resistance and resistance to breakage. Through alloying, reasonable selection of materials and heat treatment processes, the working performance of rolls can be significantly improved to ensure high efficiency and high quality during rolling.

In order to increase the service life of the rolls, the performance optimization of steel and cast iron rolls should be combined with actual production needs, and appropriate materials and manufacturing processes should be selected. This can not only improve production efficiency, but also reduce maintenance costs and ensure product stability and consistency.