Introduction

Rolling mill rolls are essential tools in the steel and metal processing industry. These rolls play a crucial role in reducing the cross-section of the material being rolled, whether for sectional or flat products. They are subjected to high loads, wear, and extreme stress conditions. Despite advancements in rolling technology, rolls have always remained the most critical component in rolling mills. Understanding the metallurgy of rolling mill rolls is key to optimizing their performance and longevity.

Composition and Classification of Rolling Mill Rolls

Rolling mill rolls are manufactured from a variety of materials depending on their application and performance requirements. The main types of rolls include:

1. Cast Iron Rolls

Chilled Cast Iron Rolls – High hardness on the outer surface due to rapid cooling during casting.

Indefinite Chilled Cast Iron Rolls – A blend of hardness and toughness, widely used for rolling long products.

Alloyed Cast Iron Rolls – Enhanced with elements such as chromium, nickel, and molybdenum to improve wear resistance.

2. Nodular Cast Iron Rolls

Pearlitic Nodular Cast Iron Rolls – Excellent strength and wear resistance.

Bainitic Nodular Cast Iron Rolls – Higher toughness with superior fatigue resistance.

High Chromium Cast Iron Rolls – Exceptional hardness and wear resistance, ideal for hot rolling applications.

3. Steel Rolls

Forged Steel Rolls – Used in high-stress environments where strength and toughness are essential.

High-Speed Steel (HSS) Rolls – Offer superior wear resistance, high-temperature strength, and longevity.

Tungsten Carbide Rolls – Highly wear-resistant rolls used in specialized applications like wire rod rolling.

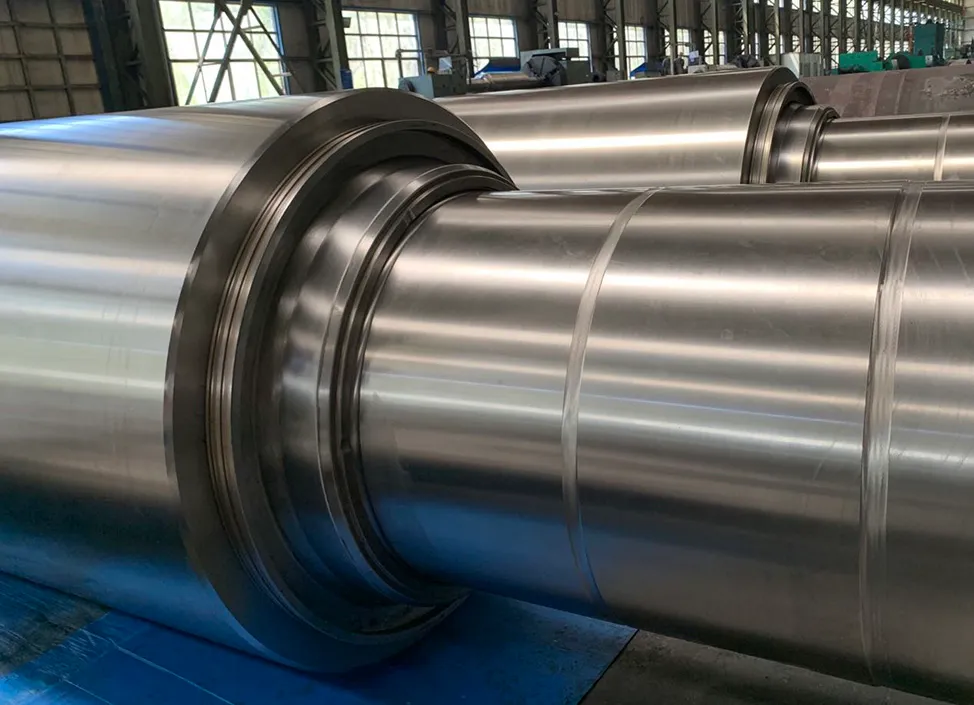

Structure and Design of Rolling Mill Rolls

Rolling mill rolls consist of two main parts:

Roll Body – The central working portion of the roll that comes into contact with the metal being rolled.

Roll Necks – Located on both ends of the roll, they support the roll and transmit torque.

Depending on the application, the roll body may be smooth (plain) for rolling sheets, plates, and strips or grooved for rolling shaped materials such as rebar, beams, and angles.

Key Metallurgical Properties of Rolls

The performance of rolling mill rolls depends on their metallurgical properties, which include:

1. Hardness and Wear Resistance

Rolls must have a hard outer surface to resist wear during continuous contact with the workpiece.

High-carbon and alloyed materials enhance the hardness of the roll.

2. Strength and Toughness

Rolls experience extreme compressive forces; therefore, they require high strength to prevent breakage.

Toughness ensures that the roll does not crack or fail under heavy loads.

3. Thermal Stability

During rolling, rolls are exposed to extreme heat, requiring them to maintain structural integrity at high temperatures.

High-speed steel and carbide rolls are known for their excellent thermal resistance.

Manufacturing Processes of Rolling Mill Rolls

The production of high-performance rolls involves several metallurgical techniques, including:

1. Centrifugal Casting

Used for manufacturing high-quality rolls with a hard outer layer and tough core.

Ensures uniform distribution of alloying elements.

2. Static Casting

Traditional method used for large rolls with customized alloy compositions.

Produces rolls with excellent internal structure.

3. Forging

Used for steel rolls requiring superior mechanical properties and impact resistance.

Enhances grain structure and overall durability.

Common Failure Modes of Rolls

Despite their robust design, rolling mill rolls can fail due to:

Wear and Surface Fatigue – Caused by continuous contact with hard materials.

Thermal Cracking – Due to high-temperature fluctuations in hot rolling applications.

Mechanical Overload – Excessive loads can lead to roll breakage.

Spalling – Small surface cracks that develop into larger fractures over time.

Conclusion

Rolling mill rolls are crucial components in steel and metal manufacturing. Their metallurgy, material composition, and design significantly impact the efficiency and quality of the rolling process. By selecting the appropriate roll type and optimizing its metallurgical properties, rolling mills can enhance productivity, reduce downtime, and extend roll life. As rolling technology continues to evolve, advanced materials and manufacturing processes will further improve the performance of rolling mill rolls.