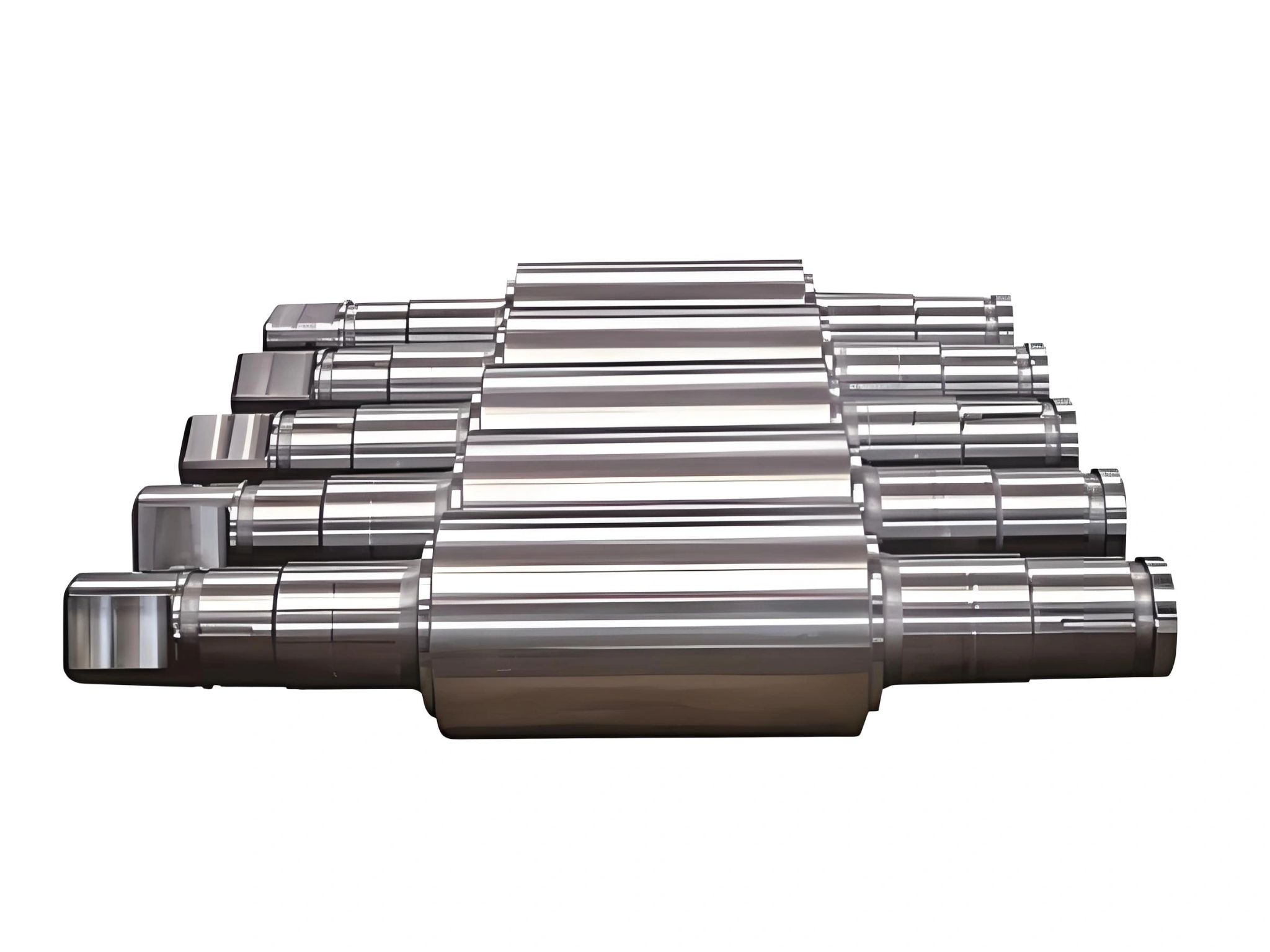

The production of our mill rolls involves three key processes, each carefully controlled to ensure the highest quality.

The forging process begins with the selection of high-quality steel materials, which are then forged in a high-temperature environment. This step requires strict control to ensure the surface quality and texture of the rolls.

Our factory is equipped with advanced forging technology, allowing for high-precision forging and efficient production of steel billets, guaranteeing the quality of the rolling rolls.

Following forging, the rolls undergo heat treatment to improve their hardness and wear resistance. This process includes heating, geothermal treatment, and quenching. Our factory uses internationally advanced heat treatment technology to ensure the rolls meet industry standards for quality.

The processing process is the most intricate and detailed stage of roll manufacturing. With a skilled team and professional equipment, our factory can efficiently process complex rolls in a short amount of time.

Through these processes, our factory’s forging mill roll production meets strict requirements, with each step carefully monitored by professional technicians to ensure the highest quality. Compared to other manufacturers, we offer several advantages:

A rigorous quality management system with dedicated inspectors at each stage of production to ensure consistent quality.

Years of production experience and mature processes, enabling us to meet the diverse needs of our customers.

A short production cycle, ensuring fast delivery times and minimizing customer downtime.

Our factory’s production process ensures consistent roll quality and a fast production cycle. With a strong quality management system and advanced technology, we are well-equipped to meet the specific needs of our customers.