The roller tensile strength test mainly has the following steps:

1. Slicing

Cut the 30mm thick round test block outside the effective length of the lower roll neck of the roller.

2. Take the test bar blank

Cut the pull rod blank with an online cutting machine, and the length meets the requirements of the test bar drawing.

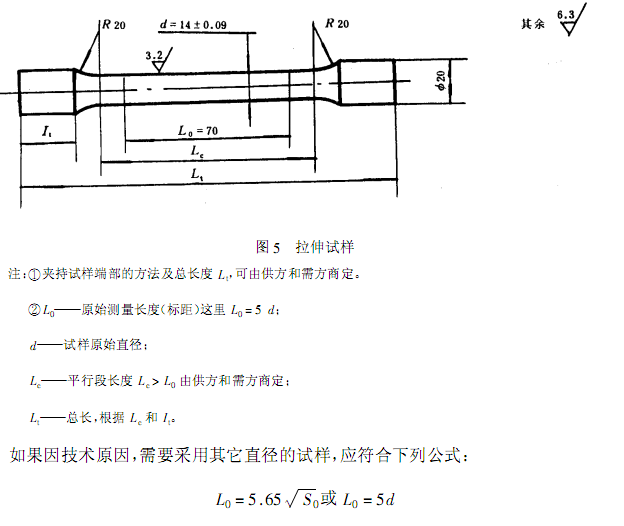

3. Process the test bar (see the attached figure for details)

Process the test bar on the lathe according to the requirements of the drawing, with a surface roughness of Ra3.2, and all arcs have smooth transitions, without knife marks and knife marks.

Grind burrs with fine sandpaper. Check the geometric dimensions of the test bar and record the original data.

4. Tensile strength test

① Turn on the power and reset the tensile machine.

② Clamp the test bar in the tensile machine and carefully check whether it is clamped in place.

③ The instrument pointer returns to zero.

④ Select a suitable pound load.

⑤ Open the oil inlet valve and close the oil outlet valve.

⑥ Turn on the power of the hydraulic motor, and the tensile machine starts working until there is a loud noise and the test bar breaks.

⑦Record pointer readings.

⑧Calculate strength.

⑨Record and archive.