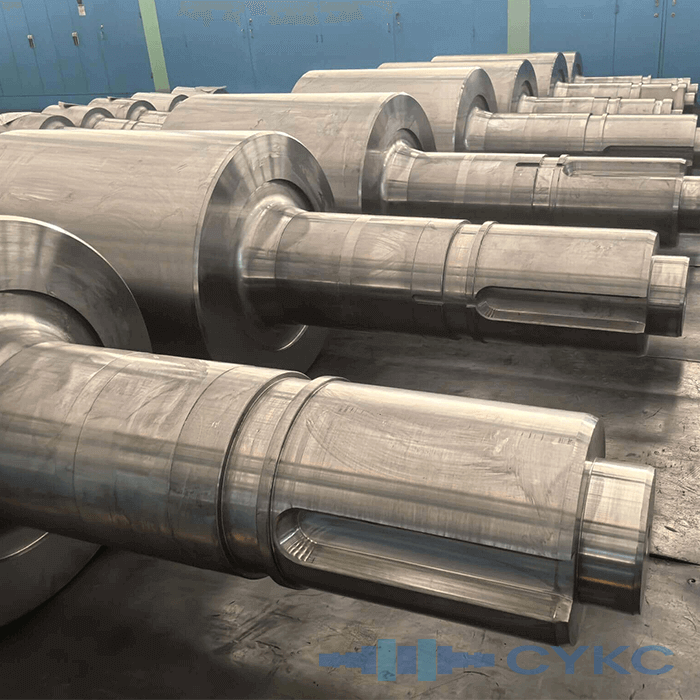

Cast iron rolls are essential components in the steel rolling industry. They offer excellent wear resistance, heat resistance, and strength under high loads. With a carbon content of 2.5% to 3.5%, cast iron rolls are categorized based on material composition and internal structure. Choosing the right roll type is crucial for ensuring product quality and extending equipment life.

1. Ordinary Cast Iron Rolls

Ordinary cast iron rolls include:

Chilled Cast Iron Rolls

Made by utilizing the self-supercooling of molten iron and the chilling effect of the mold surface, these rolls form a hard white layer on the surface, providing excellent wear resistance.

Infinite Chilled Cast Iron Rolls

Positioned between chilled and gray cast iron, these rolls contain graphite in the matrix without a clear boundary between the working layer and core. They offer moderate hardness and toughness.

Ductile Iron Rolls

These rolls contain nodular graphite and are available in composite and spherical core types.

Applications: thin plate mills, bar mills, wire mills, and section mills.

2. High Nickel-Chromium Infinite Chilled Composite Cast Iron Rolls

These rolls are produced using full flushing or centrifugal composite casting. They contain high levels of chromium, nickel, and molybdenum. The matrix has a large amount of carbide, offering excellent wear resistance. Graphite provides thermal resistance and toughness.

Applications: medium and wide plate mills, strip mills.

3. High Chromium Composite Cast Iron Rolls

Manufactured by centrifugal casting, these rolls use high chromium white cast iron (12-22% Cr) for the outer layer and ductile iron for the core and neck. The matrix contains Cr₇C₃, Mo₂C, and Cr₂₃C₆ carbides, ensuring outstanding wear resistance.

Applications: front working rolls in rough and finishing stands of hot strip mills, wide and medium plate mills, and small steel rolling mills.

4. Alloy Ductile Iron Rolls

These rolls feature high tensile strength and excellent wear resistance due to the spheroidal graphite distribution throughout the roll. The matrix is carbide with pearlite or bainite. Alloy ductile iron rolls are either integrally cast or produced via centrifugal composite casting.

Applications: primary rolling mills, bar rolling mills, seamless pipe mills.

Conclusion

Understanding the characteristics of different cast iron rolls is key to optimizing rolling mill performance. From cost-effective ordinary rolls to high-performance composite rolls, each type serves a unique role in steel processing. Choosing the right material ensures better wear life, efficiency, and product quality.

Contact Us

CYKC GROUP is a professional manufacturer of various cast iron rolls and roll machining equipment. We provide:

Customized roll solutions

Advanced centrifugal casting technology

Reliable after-sales support

📧 Email:cykc@cykcgroup.com.cn

🌐 Website: www.cykcmillrolls.com

Let us know your roll requirements — we’ll get back with the best solution!