Introduction

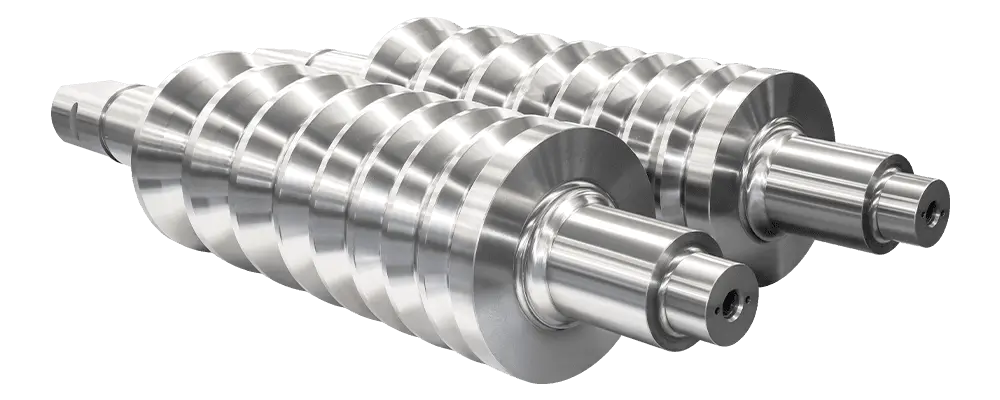

In steel production, mill rolls are essential consumable components that directly impact rolling efficiency and product quality. However, due to continuous high-pressure operation, rolls suffer from wear and fatigue, leading to frequent replacements and high maintenance costs. Traditional repair methods like surfacing and electroplating struggle to meet modern steel industry's demands. Is there a better solution? Yes—laser cladding technology!

What is Laser Cladding?

Laser cladding is an advanced surface treatment technology that applies a high-hardness, wear-resistant alloy layer onto the roll surface. This process significantly enhances the durability and lifespan of rolls, outperforming traditional repair methods in every aspect.

Why Choose Laser Cladding?

Superior Wear Resistance and Hardness

Compared to conventional surfacing and electroplating, laser cladding creates a denser, harder, and more wear-resistant surface. Rolls treated with laser cladding withstand intense rolling conditions, reducing wear and tear.

Enhanced Surface Quality

A smooth roll surface ensures high-quality steel products. Laser cladding precisely controls layer thickness and smoothness, minimizing defects and improving the finish of rolled steel. This means fewer rejections and higher product value.

Massive Cost Savings

Instead of frequently replacing worn-out rolls, laser cladding allows steel mills to repair and reuse existing rolls, reducing costs. The extended service life of laser-clad rolls also decreases maintenance frequency, leading to long-term savings.

Applications of Laser Cladding in Mill Rolls

Backup Rolls: These rolls endure extreme pressure and friction. Laser cladding strengthens them, more than doubling their lifespan and lowering replacement costs.

Work Rolls: Directly in contact with steel, work rolls need a smooth, durable surface. Laser cladding improves hardness and wear resistance, reducing surface roughness by over 50%, ensuring better steel quality.

Special-Shaped Rolls: Their complex shapes make traditional repairs difficult. Laser cladding allows precise material deposition, restoring their original dimensions and surface finish with high accuracy.

Conclusion

Laser cladding is revolutionizing roll maintenance in the steel industry. With its superior wear resistance, cost-saving benefits, and ability to enhance steel quality, it is the ultimate solution for steel mills looking to maximize efficiency and profitability. Why replace rolls when you can make them last longer? Choose laser cladding and stay ahead in the industry!