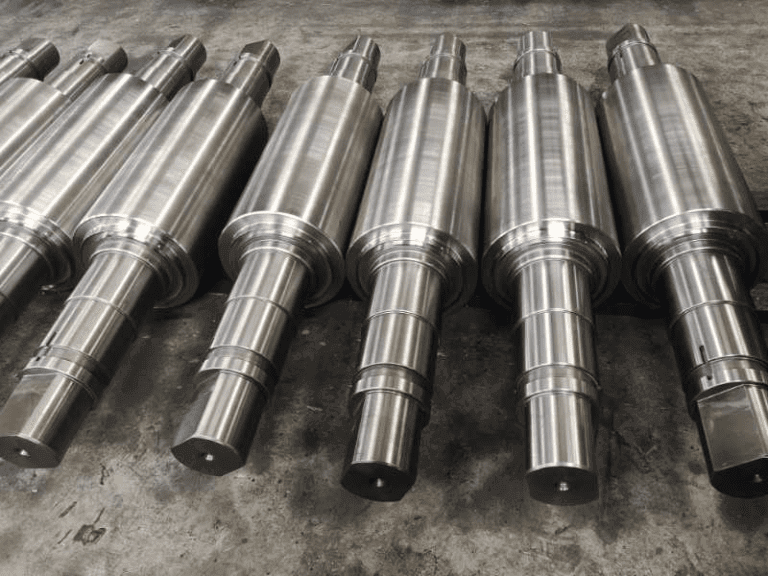

Centrifugal casting rolls are widely used in the steel and metal processing industries. This casting method pours molten metal into a fast-rotating mold. Under centrifugal force, the metal forms a dense, strong structure. These rolls offer many advantages for demanding applications.

What Are Centrifugal Casting Rolls?

Centrifugal casting rolls are produced by spinning the mold at high speed while adding molten metal. This process helps remove impurities and improve the final quality of the roll. The working layer forms first under rotation. After that, the core is added through static casting.

Key Characteristics of Centrifugal Casting Rolls

Centrifugal casting rolls stand out because of their structure and performance. Here are their main features:

Fewer inclusions – The centrifugal force removes impurities during solidification.

Low porosity – Gas and shrinkage defects are minimized.

Dense metal structure – The metal grains are compact and uniform.

Slow hardness drop – The hardness stays more consistent through the roll’s depth.

Double or multi-layer casting – This allows a hard surface with a tough core.

Metal segregation control – Helps adjust composition across layers.

Technical Key Points in Producing Centrifugal Casting Rolls

To ensure quality, several technical aspects must be controlled during production:

1. Strong Working Layer

The working layer must have high wear resistance and resist accidents. This layer touches the rolled material, so strength is critical.

2. Reliable Bonding Layer

The bond between the outer layer and the core must be strong. Any weakness here may cause the roll to fail during operation.

3. Controlled Hardness Gradient

The working layer’s hardness should drop slowly to maintain performance and avoid cracks.

4. Improved Core Properties

Spheroidizing the core increases strength and toughness. This improves the overall mechanical properties of the roll.

Conclusion

Centrifugal casting rolls offer superior structure, durability, and flexibility. Their production requires strict control over metallurgy and casting methods. For steel mills and metal processing plants, choosing centrifugal casting rolls means longer service life and better product quality.

Contact Us

Looking for reliable centrifugal casting rolls?

CYKC Group offers professional roll manufacturing and technical support.

Email: cykc@cykcgroup.com.cn

Website: www.cykcgroup.com

We’re ready to help you choose the right rolls for your mill. Contact us today!