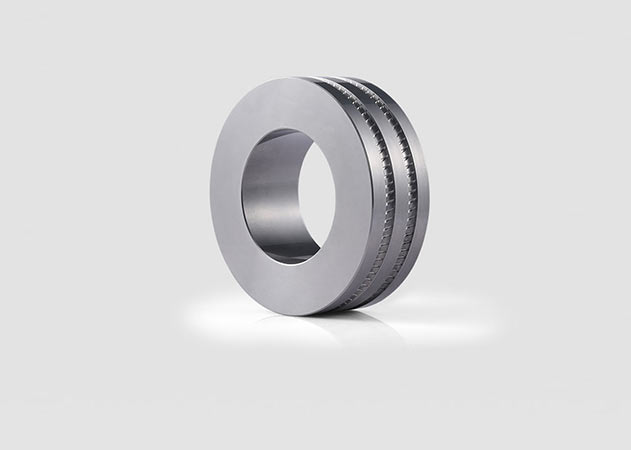

Unmatched Wear Resistance

Tungsten carbide rings are the most wear-resistant rings available, ensuring long-lasting performance even in demanding industrial environments.

Exceptional Hardness

Tungsten carbide is approximately 10 times harder than gold, 5 times harder than tool steel, and 4 times harder than titanium.

Durability and Luster

Thanks to their extreme hardness, tungsten carbide rings maintain their shape and shine far longer than any other type of ring on the market.

Permanent Polishing

Known as the "permanent polishing ring," tungsten carbide rings retain their polished finish with minimal maintenance.

Bend-Resistant

Unlike traditional metal rings, tungsten carbide rings do not bend, ensuring consistent performance over time.

Applications

Tungsten carbide roll rings are essential in various rolling applications, including:

Bar and wire rod mills

Hot and cold strip mills

Plate rolling mills

Non-ferrous mills

Seamless pipe rolling mills

High-speed finishing mill roll sleeves

Material Characteristics

High-speed steel (HSS) roll rings are manufactured in compliance with the national cast steel roll standard GB/T1503-2008. These rings are composed of a steel-based alloy enriched with vanadium, nickel, tungsten, molybdenum, niobium, and cobalt. Key characteristics include:

Carbon content: <1.6%

Phosphorus content: <0.03%

Chromium content: <5%

Sulfur content: <0.03%

These carefully controlled compositions ensure superior wear resistance, impact toughness, and resistance to micro-cracks, block loss, and ring bursts. The precise control of tungsten content prevents segregation during centrifugal casting, resulting in minimal hardness drop after re-grinding and consistent steel-passing performance.

Manufacturing Process

Our production process is meticulously designed to ensure the highest quality:

Tooling Design: Customized tooling for precise specifications.

Modeling: Detailed modeling to meet design requirements.

Smelting: High-temperature smelting to achieve optimal alloy composition.

Centrifugal Casting: Ensures uniform density and structural integrity.

Thermal Insulation: Maintains consistent cooling rates to prevent defects.

Unpacking and Flaw Detection: Rigorous inspection to identify and eliminate imperfections.

Heat Treatment: Enhances hardness and durability.

Hardness Testing and Finishing: Precision machining and testing to meet exact specifications.

Metallographic Inspection: Ensures optimal microstructure and performance.

Factory Inspection and Storage: Final quality checks before packaging and storage.

Quality Assurance

At CYKC, every roll ring undergoes three rounds of meticulous inspection to guarantee inherent quality. Additionally, all rings are tempered three times to achieve the best metallographic structure, ensuring peak performance and reliability in even the most demanding applications.

Tungsten carbide roll rings from CYKC are the ultimate choice for industries requiring high-performance, durable, and reliable rolling solutions. Contact us today to learn more about our products and how we can support your manufacturing needs!