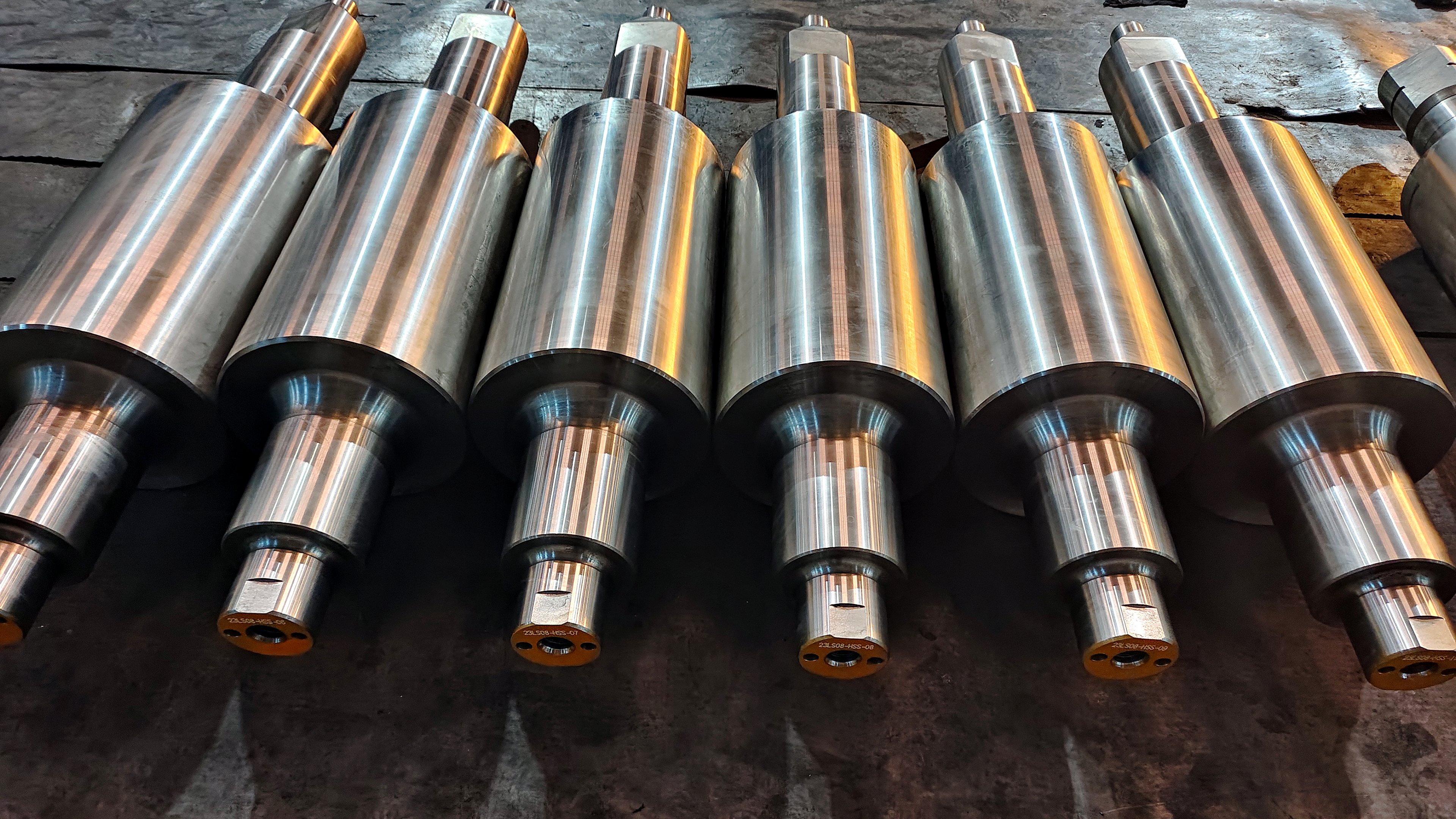

In the steel, non-ferrous metals and metallurgical industries, rolls are the core components that ensure production quality and efficiency. Choosing a suitable set of rolls can not only significantly improve the surface quality and dimensional accuracy, but also extend the service life of the equipment, reduce downtime costs and enhance the overall profitability.

We offer a full range of high-quality rolls

CYKC GROUP offers a variety of types of industrial rolls to meet various rolling requirements:

High alloy cast steel rolls: Suitable for rough rolling and hot rolling, with strong resistance to hot cracking and impact resistance.

Forged steel rolls: High strength, dense structure, widely used in heavy-duty reversible rolling mills.

Infinite cold-hardened cast iron rolls: High surface hardness, suitable for cold rolling and precision rolling, with excellent wear resistance.

Alloy composite rolls: With a composite structure design, the outer layer is hard and the inner layer is tough, featuring a long service life and low maintenance cost.

High-speed steel rolls (HSS) : They have good thermal hardness and strong surface wear resistance, making them suitable for high-speed precision rolling production lines.

Why choose our roller products?

Stable performance: Advanced smelting and heat treatment processes ensure uniform hardness, resistance to hot cracking and spalling.

High machining accuracy: CNC equipment for full machining, control accuracy can reach ±0.01mm.

Longer service life: Optimized alloy formulation and surface strengthening improve wear resistance by more than 30%.

Custom service: CUSTOM size, material and hardness are available according to customer drawings or conditions of use.

Fast delivery: Standard models are in stock and special specifications are delivered in short intervals.

Provide one-stop service support

We not only offer high-quality roll products, but also provide the following service guarantees:

Site installation and commissioning.

Grinding refurbishment and reprocessing

Technical guidance and selection advice.

Raw materials and hardness test report.

Export standard packaging and global distribution.

Typical application scenarios

Hot-rolled strip steel wire.

Cold-rolled stainless steel and copper-aluminum wires.

Precision rolled sections of bar and wire rods.

Section steel rolling unit.

Special alloy rolling production line.

Contact us now for a quote and technical advice!

Let us help you find the most suitable roll solution to enhance production line efficiency and reduce operating costs.