Introduction

High-nickel-chromium indefinite chill cast iron rolls are critical components in modern rolling mills, offering exceptional wear resistance, thermal stability, and fatigue strength. Their unique microstructure—comprising bainite, retained austenite, and hard carbides—is achieved through specialized alloy design and controlled solidification. This article explores the metallurgical characteristics, phase transformation mechanisms, and industrial performance of these advanced rolls.

1. Solidification & Microstructure Formation

During casting (via composite pouring, bottom gating, or centrifugal methods), the high-alloy molten iron rapidly solidifies under the chilling effect of the mold, resulting in:

Dominant Columnar Crystals: Aligned growth perpendicular to the cooling direction.

Directional Graphite/Carbide Precipitation: Distributed along inter-dendritic regions (see Fig. 1-50).

Key Alloying Elements & Their Roles

Element | Function |

Nickel (4.0–4.5%) | Stabilizes austenite; enhances toughness |

Chromium (1.6–1.85%) | Promotes carbide formation; improves hardness |

Molybdenum/Manganese | Delays pearlite transformation; refines bainite |

2. Phase Transformation Mechanism

The high Ni/Cr content significantly alters the Bs (Bainite Start) temperature (calculated as 338–441°C per empirical formula):

Austenite Stability: Suppresses pearlite formation, favoring bainite/martensite during continuous cooling.

Retained Austenite (13–15%): Remains due to insufficient heat dissipation during phase change.

Heat Treatment Effects

Tempering: Converts as-cast bainite/martensite into:

Tempered Bainite (Improved toughness; Fig. 1-51)

Tempered Sorbitte (Balanced strength-ductility; Fig. 1-52)

3. Graphite & Carbide Distribution

Free Graphite (2–5%): Appears as vermicular (worm-like) or short-flake morphologies (Figs. 1-53/1-54), concentrated in columnar crystal boundaries.

Carbides (25–30%): Primarily M₇C₃-type, providing wear resistance.

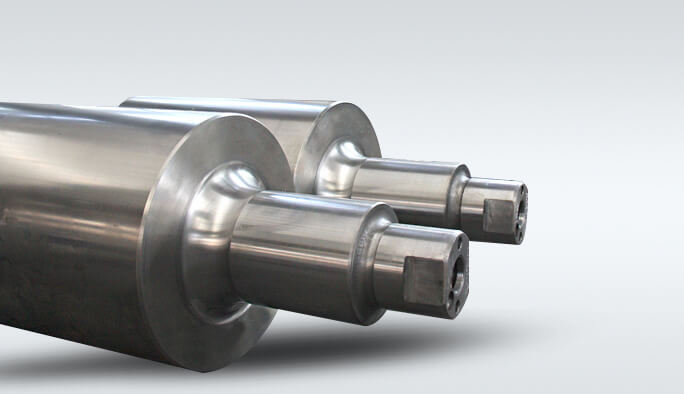

4. Core & Neck Materials

Depending on application requirements:

Roll Necks: High-ductility gray iron for shock absorption.

Roll Cores: High-strength ductile iron (nodular graphite) to withstand bending stresses.

5. Industrial Advantages

Extended Service Life: 3–5x longer than conventional rolls.

Thermal Crack Resistance: Stable under cyclic heating/cooling.

Customizable Microstructure: Tailored via alloying and heat treatment.

Conclusion

The high-nickel-chromium indefinite chill cast iron rolls achieve optimal performance through controlled bainitic transformation, carbide dispersion, and graphite morphology. Their adaptability to severe rolling conditions makes them indispensable for hot/strip mills, section rolling, and high-speed wire production.