In the critical stage of precision rolling, traditional roller solutions have failed to meet the extreme demands of modern industries for efficiency, precision, and cost. Leveraging over three decades of profound manufacturing experience and cutting-edge material technology, CYKC GROUP has introduced the hard alloy composite roller ring (tungsten carbide titanium TC ring), which has become a strategic choice for numerous advanced steel enterprises worldwide to achieve capacity expansion and cost optimization.

I. Customer's Core Challenges and Our Solutions

Challenge: In the fine rolling and splitting rolling processes of bar and wire rods, traditional high-nickel-chromium rollers and high-speed steel rollers encounter the problem of limited steel passing per slot, rapid wear, and frequent roller replacement, which leads to increased production costs and frequent equipment downtime, seriously affecting the continuity of the production line.

Our answer: Hard alloy composite roller rings. It is not a simple replacement, but rather a comprehensive project:

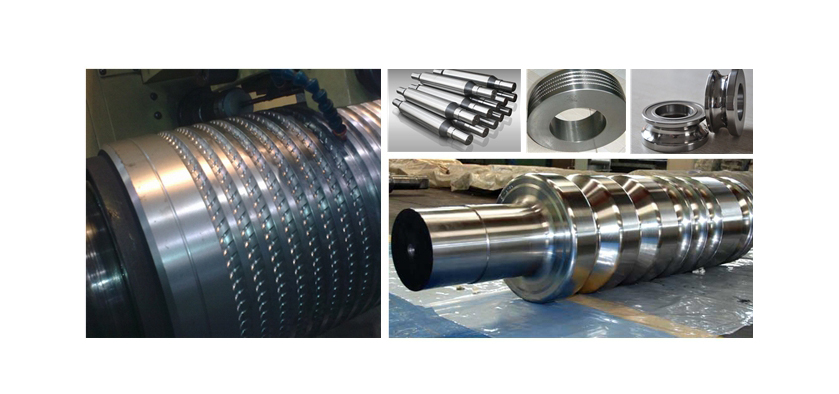

Innovative structure: Composed of a high-maintenance hard alloy working ring, a high-strength alloy steel core shaft, and patented connecting components, it achieves the optimal performance combination of "outer hardness and inner toughness".

Disruptive performance: Utilizing independently developed specialized hard alloy material, it features unparalleled wear resistance, high strength and toughness, ensuring stable performance under extreme rolling conditions.

II. Why choose CYKC's composite roller ring?

Economic multiplier

The steel throughput in a single slot has been significantly increased, greatly reducing the number of slot changes and roll replacements.

Significantly reduce the cost of steel rolling per ton, with a clear return on investment.

Reduce unplanned downtime caused by changing rolls and effectively improve the overall equipment efficiency.

The guardian of quality stability

The shape retention of the roller grooves is extremely good, ensuring that the dimensional tolerance of the products is highly stable.

Provide better surface quality and consistent mechanical properties for products such as rebar and round steel.

Customized design based on operating conditions

We are not only manufacturers but also solution partners. The professional team of CYKC will conduct a detailed analysis of your specific working conditions, and accordingly customize the material formula, roller ring profile, and composite structure to ensure a "perfect fit" between the product and your production line.

Verified industry reputation

The product has been successfully applied in the finishing rolling machines of many well-known steel enterprises worldwide, and its outstanding performance has been widely verified.

We have a complete international-level supply chain and quality control system covering material research and development, precise manufacturing, and full-process quality inspection.

III. Proof of Customer Trust

"We have been seeking a roller ring solution that can handle the high-strength steel rolling process. Traditional roller rings wear out too quickly and cause significant quality fluctuations. After collaborating with the CYKC group team, the customized hard alloy composite roller rings they provided completely transformed our finishing rolling process. The throughput per single roll was significantly increased, the cost per ton of steel decreased significantly, and the dimensional stability of the products reached the highest level in history. This was not just a replacement of components, but an upgrade of the production process." - Production Director of a globally renowned steel group

IV. Initiating Your Efficiency Revolution

In the face of fierce market competition, improvements in the finishing rolling process can directly translate into cost advantages. CYKC GROUP is willing to serve as your reliable long-term partner by leveraging its advanced hard alloy composite roll ring technology and deeply customized services.

Next step:

Please provide your operating conditions (type of rolling, speed, existing problems).

Obtain a preliminary benefit analysis report to quantify the potential cost savings and efficiency improvements.

Arrange a technical exchange session and let our engineers tailor the best solution for you.

Contact us and join hands to embark on the future of high-efficiency and high-stability precision rolling production.

Contact us: cykc@cykcgroup.com.cn