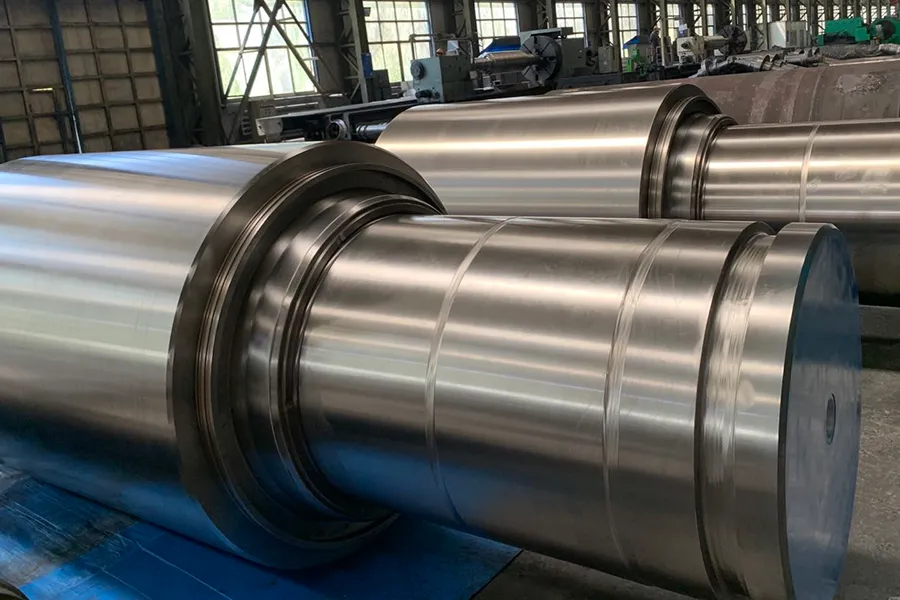

Bainite Roller (bainite roller) with its superior mechanical properties, gradually become the first choice in many rolling processes. This article will discuss the application of Bainite Roller in the finishing stand of continuous rolling mill, the pre-finishing stand of high speed wire mill, the middle and front finishing stand of small section mill, and the sheet mill and straightener, and analyze its advantages in detail.

Definition and characteristics of Bainite Roller

Bainite Roller is made of bainite structure material, this structure in the steel material to form a hardness and toughness balance of the micro structure. The bainite structure is between pearlite and martensite, and has high abrasion resistance, high temperature resistance and excellent impact resistance. After heat treatment, the bainite roll can show excellent mechanical properties, so that it can maintain a long service life under high load, high temperature and high strength working environment.

The main features of bainite rolls include:

· High hardness and wear resistance: suitable for long-term use under high temperature and high pressure conditions to reduce wear.

· Thermal fatigue resistance: stable under high temperature change and thermal shock.

· Good impact toughness: can resist the violent collision at high speed rolling, reduce damage.

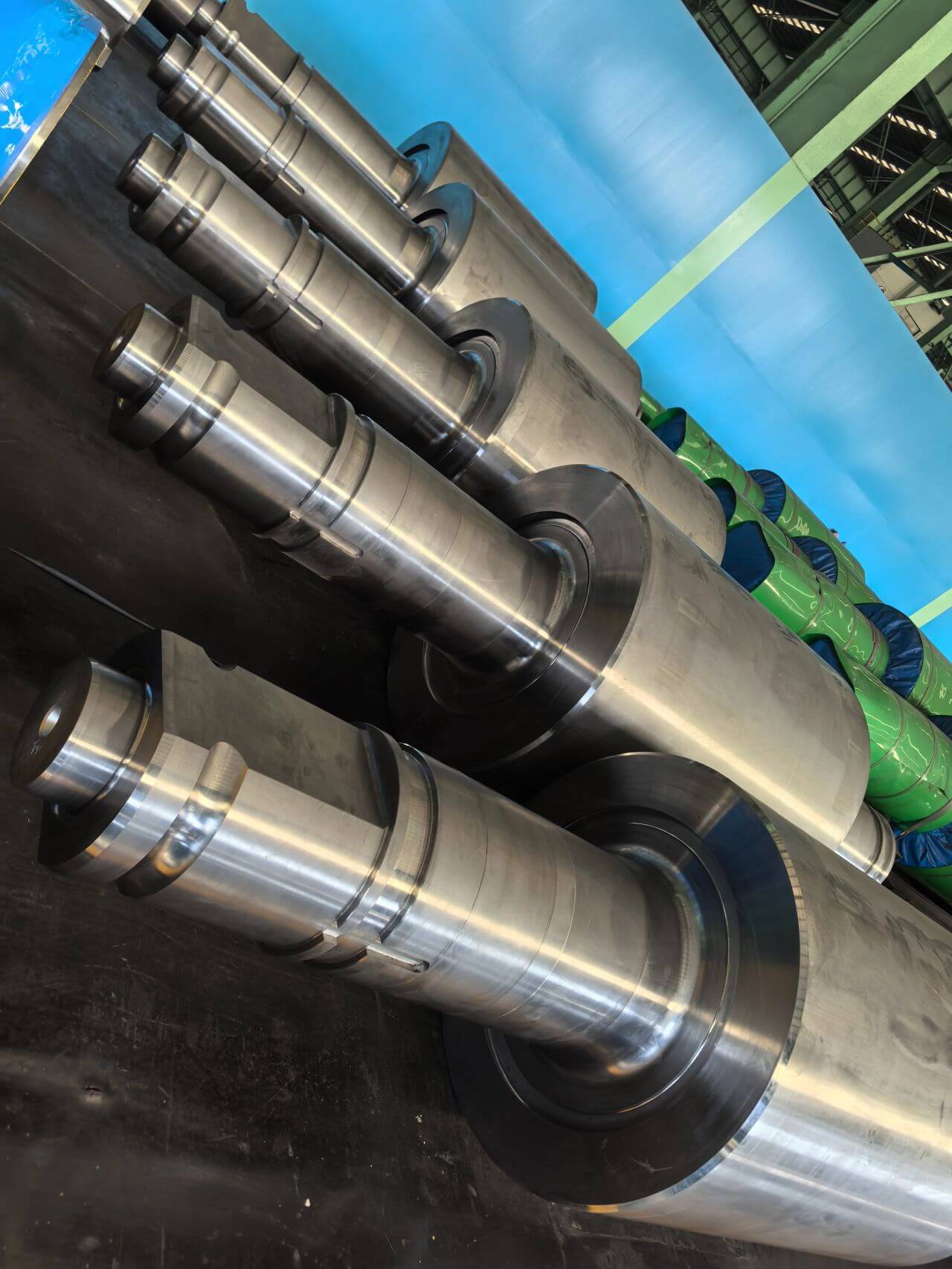

Application of Bainite Roller in different rolling mills

1. Finishing rack of continuous rolling mill

In a continuous mill, the finishing rack is responsible for the final finishing and shaping of the rolled steel. Bainite rolls are widely used in this process, especially in the production of strip and bar steel, to ensure the surface smoothness and dimensional accuracy of the product. Bainite Roller's excellent wear resistance extends the service life of the high speed friction of the finishing frame while reducing surface defects.

2. Pre-finishing rack of high-speed wire mill

In the pre-finishing stand of high speed wire mill, bainite roll can improve the surface quality and production efficiency of steel. Due to the huge friction between the steel and the roll during the high-speed rolling process, the Bainite Roller, with its superior wear resistance, can withstand a longer period of work without excessive wear or cracks, maintaining efficient rolling quality.

3. Middle and front finishing frame of small section mill

In small section rolling mill, bainite rolls are widely used in middle and front end finishing stand. Small section steel such as Angle steel, channel steel, etc., need to be rolled several times to achieve the required size and surface quality. The high wear resistance and good impact toughness of Bainite Roller can effectively prevent damage under high-speed and high-intensity rolling and ensure the accuracy of the final product.

4. Sheet mill and straightener

Bainite rolls are also suitable for sheet mills and straighteners. Sheet rolling requires strict dimensional control and surface quality, and Bainite Roller, through its superior surface hardness and impact resistance, can help reduce surface defects and non-uniformity during the rolling process, ensuring high precision and good surface quality of the steel plate.

Bainite Roller's strengths

The high hardness of the Bainite Roller allows it to withstand greater wear during high-speed rolling without rapidly losing performance. This makes it have obvious advantages in high-load working environment, especially in the finishing process of strip and bar steel.

Thermal Fatigue resistance Bainite Roller effectively resists the negative effects of thermal shock and temperature changes. In the continuous rolling process, the roll will experience high temperature changes, and the bainite roll can maintain stable working performance by its thermal stability, extend the service life.

High impact resistance When rolling high-strength steel, Bainite Roller can effectively resist the impact force caused by high-speed collisions, reducing the risk of cracks and damage, and ensuring stability and reliability in the production process.

Improving Rolling quality Bainite Roller helps to improve the quality of the final steel. In the rolling process of steel, due to its excellent wear resistance and hardness, it can effectively reduce surface defects and deformation, and ensure that the rolled steel size is accurate and the surface is smooth.

Market demand and development prospect of Bainite Roller

With the continuous improvement of production efficiency and product quality requirements in the steel industry, Bainite Roller is gradually becoming the tool of choice for all types of rolling mills due to its excellent performance. In the future, with the continuous development and innovation of steel production process, the application prospect of Bainite Roller is broad, especially in the field of high-speed and high-precision rolling, and will play a more important role.

Technological advances have led to continuous optimization of the Bainite Roller manufacturing process, and it is expected that its application in high temperature, high strength and high precision rolling process will be further expanded.

Sum up

As a high performance roll material, Bainite Roller has shown great application potential in rolling mills in many fields due to its excellent wear resistance, thermal fatigue resistance and impact resistance. Whether in the finishing stand of a continuous mill, the pre-finishing stand of a high-speed wire mill, or in a small section mill and sheet mill, Bainite Roller can effectively improve production efficiency, ensure steel quality, and greatly extend the service life of the roll. With the development of the steel industry, the application prospect of Bainite Roller will be broader and become an indispensable tool in steel production.