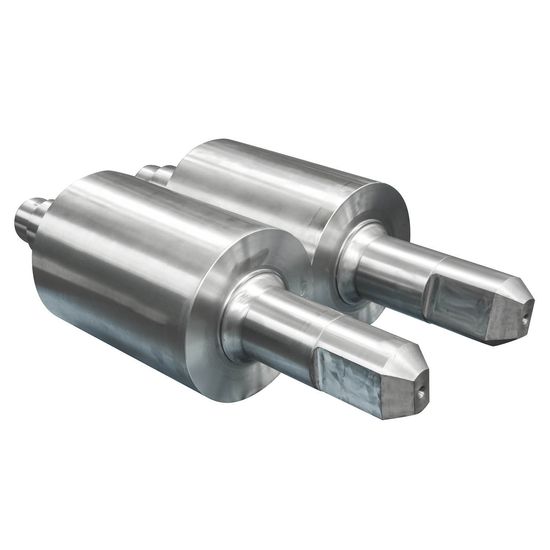

In modern steel production, as one of the key tools, the roller directly affects the production efficiency, cost and product quality. Bainite Ductile Cast Iron Rolls (bainite ductile cast iron rolls) with its unique material characteristics, gradually become a widely used choice in steel production. This article will explore how Bainite Ductile Cast Iron Rolls can help steel producers optimize production processes and economics by increasing production efficiency, reducing production costs and extending service life.

Bainite Ductile Cast Iron Rolls to improve productivity

Bainite Ductile Cast Iron Rolls are widely used in pre-rolling units and intermediate rolling units. Compared to conventional materials, these rollers have higher wear resistance and strength, and can withstand higher loads and higher speed rolling processes. Its performance is particularly outstanding in high-speed rolling, which can effectively reduce the production halt caused by roller wear.

Increased production efficiency: Thanks to the wear resistance of rollers, the production line runs more smoothly and equipment downtime is significantly reduced. This means that production can be carried out more continuously, reducing downtime due to equipment failure or maintenance.

Reduce downtime in the production process: The high wear resistance of Bainite Ductile Cast Iron Rolls enables the replacement of rolls during the production process to be greatly reduced, reducing downtime and improving the overall operating efficiency of the line.

Reduce production costs

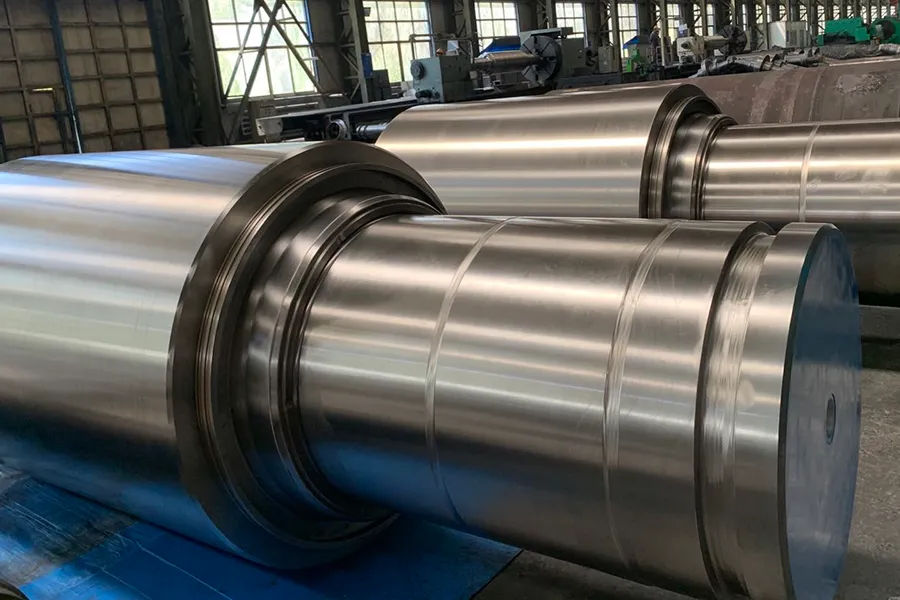

Iron and steel production enterprises often face the problem of frequent roller replacement and high maintenance cost. Bainite Ductile Cast Iron Rolls reduce the time and cost required to replace rolls thanks to their excellent wear resistance and extended service life.

Extended service life: The excellent performance of Bainite Ductile Cast Iron Rolls makes the service life of the rolls greatly extended. Steel production enterprises do not need to change rolls frequently, reducing maintenance costs.

Reduced downtime costs: Less frequent replacement of rolls means less downtime of the production line, thereby reducing losses caused by production disruptions.

Excellent wear resistance

In the process of high speed rolling, rollers need to withstand a lot of friction and wear. Bainite Ductile Cast Iron Rolls, through their unique material structure, provide excellent wear resistance and can maintain stable working conditions under extreme conditions.

Withstand high friction: Bainite Ductile Cast Iron Rolls can resist the intense friction generated by high-speed rolling, reducing the loss of rolls.

Contribution of wear resistance to production stability: Due to its excellent wear resistance, the roller can maintain stable performance for a long time, reduce the fluctuation caused by equipment failure in the production process, and improve the stability of production.、

Conclusion

As a high performance roll material, Bainite Ductile Cast Iron Rolls have significant production advantages. It can not only significantly improve the efficiency of steel production, reduce downtime in production, but also reduce production costs and extend the service life of rollers. For steel producers, choosing Bainite Ductile Cast Iron Rolls is a wise decision with long-term economic benefits.

By using this high-performance roller, companies can improve production efficiency and reduce maintenance costs, thus gaining an advantageous position in the fierce market competition.

Contact us:

Email:cykc@cykcgroup.com.cn