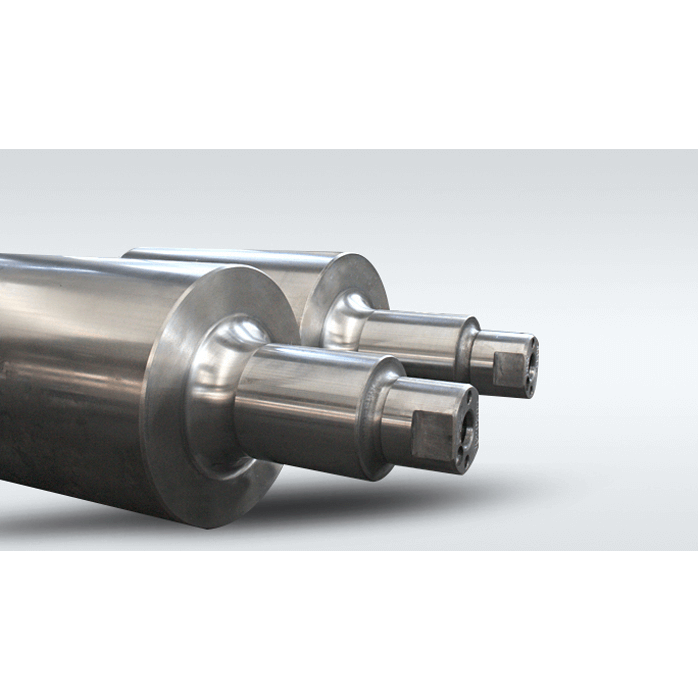

In today's highly efficient steel production, rolls, as the core components of rolling mills, their performance directly determines the efficiency, cost and product quality of the production line. In the face of the extreme requirements for strength, wear resistance and stability of high-yield rolling mills, high-performance rolls manufactured by induction furnace melting and centrifugal casting processes have become the common choice of leading global enterprises.

Core technology: The perfect combination of induction furnaces and centrifugal casting

The centrifugal casting process we adopt, in the high-speed rotating mold, uses centrifugal force to tightly push the molten metal towards the mold wall, thereby forming an extremely dense and uniform outer layer structure of the roller body. Combining the precise temperature control and pure metallurgical effect of induction furnace smelting, this technology can effectively eliminate traditional defects such as pores and slag inclusions, ensuring that the rolls have highly consistent mechanical properties and metallographic structure from the surface to the core.

This excellent uniformity of the structure enables the rolls to demonstrate outstanding stability and fatigue resistance when subjected to huge rolling forces and thermal alternating stresses, making them particularly suitable for the high-impact environment of the primary rolling mill frame and the high-precision requirements of the finishing rolling mill frame.

Diversified material systems to address the challenges of rolling in all scenarios

To meet the specific requirements of different rolling mills and process sections, we have developed a comprehensive roll material system:

High-speed steel rolls: Renowned for their extremely high red hardness and wear resistance, they are the ideal choice for the finishing mill frames of hot-rolled strip steel, effectively maintaining the roll shape and enhancing the surface quality of the strip steel.

High-chromium cast iron rolls: They feature excellent wear resistance and good thermal fatigue resistance, and are widely used in medium and heavy plate rolling and rough rolling of steel strips.

Microalloy cast iron rolls: By refining the matrix structure through microalloying technology, the toughness and anti-surface adhesion ability are further enhanced while maintaining high strength.

The core part of the rolls is made of high-strength gray cast iron or ductile iron, providing a solid support for the entire roll body and ensuring that it meets the strict requirements of high-yield rolling mills for bending and displacement rigidity.

Performance verification: From the laboratory to the global market

The core requirements for rolls in the hot-rolled strip steel finishing mill frame are focused on: extremely high mechanical strength, excellent resistance to thermal fatigue and oxidation, outstanding wear resistance, and resistance to surface adhesion of the strip steel.

To scientifically evaluate and continuously optimize product performance, our research includes a systematic characterization and analysis of the roll surface degradation after each rolling task. By studying the microscopic morphology of wear, the trend of hot crack propagation and the state of surface oxide layer, we continuously provide feedback and optimize the material design and process parameters. For this reason, our centrifugal casting rolls have demonstrated their outstanding performance and extremely long service life in a wide range of demanding applications such as continuous rolling mills, semi-continuous rolling mills, short-run rolling mills and coil rolling mills, earning wide recognition in the global market.

Conclusion

From material innovation to process refinement, high-performance centrifugal casting rolls are the cornerstone for modern rolling technology to move towards efficient, precise and low-cost operation. We not only offer roll products that can directly enhance your production efficiency and product quality, but also are committed to being your reliable technical partner to jointly address future rolling challenges.

Email:cykc@cykcgroup.com.cn