If you want a long-term partnership with a reliable Adamite roll supplier, consider the following key factors:

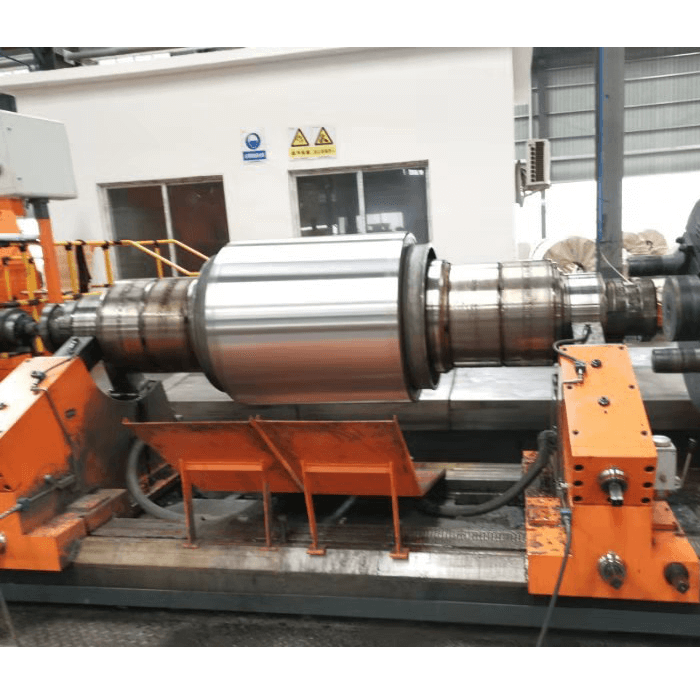

1. Mill Rolls Equipment

The manufacturing equipment directly affects the quality of Adamite rolls. From raw materials to finished products, every step depends on the precision of production equipment. Compared to alloy cast steel rolls, Adamite rolls undergo a special heat treatment process, enhancing their abrasion resistance. A supplier with advanced equipment ensures better roll performance and longevity.

2. Strict Quality Control

Quality control is essential at every stage of production. A reputable manufacturer follows strict parameters to maintain consistency and efficiency. Proper testing and inspection are necessary to guarantee high-performance mill rolls. Before choosing a supplier, ensure they implement thorough quality control measures.

3. Technological Advancement of the Manufacturer

A reliable Adamite roll manufacturer continuously invests in technological advancements. Cutting-edge technology improves product durability, strength, and efficiency. The best suppliers not only provide high-standard rolls but also offer comprehensive steel rolling solutions. Ensure the manufacturer has a professional technical team dedicated to innovation and research.

4. Delivery Time and Pricing

Timely delivery is crucial for maintaining production schedules. A good manufacturer guarantees on-time delivery to support long-term cooperation. Additionally, price plays a significant role in choosing the best-value Adamite roll supplier. It's essential to compare pricing structures while ensuring quality and service reliability.

Applications of Adamite Rolls

Adamite rolls are widely used in various rolling mills due to their excellent wear resistance and strength. They are ideal for:

Work Rolls – Used in hot rolling mills for shaping steel.

Back-up Rolls – Provide support to work rolls and reduce deformation.

Vertical Rolls for Large & Medium-Class Rough Rolling Mills – Essential for shaping large and medium steel sections.

Intermediate Rolling Mill of Section Steel and Wire Rod – Ensure precision in the rolling process.

Wire Rod and Bar Steel Roughing – Improve surface quality and efficiency.

Hot Rolling Steel Strip – Enhance durability and reduce wear during high-temperature rolling.

Choosing high-quality Adamite rolls is crucial for improving the performance of rolling mills. However, selecting a trustworthy manufacturer is equally important.

Conclusion

Finding a trustworthy Adamite roll manufacturer requires careful evaluation of equipment, quality control, technology, delivery time, and pricing. High-quality Adamite rolls improve rolling mill efficiency and durability, making it essential to partner with a reliable supplier. If you're looking for premium Adamite rolls, choose a manufacturer that meets all these criteria to enhance your steel rolling operations.

By considering these factors, you can ensure a long-term partnership with a dependable supplier, leading to better production efficiency and cost savings.